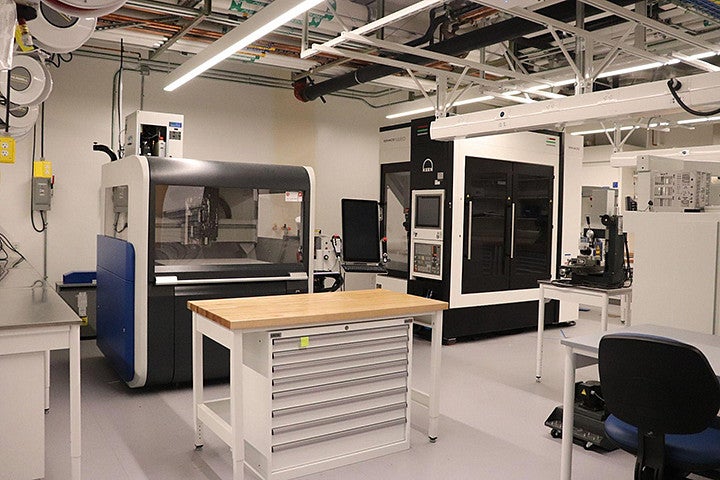

The Knight Campus is home to a rapid prototyping facility with leading-edge tools for rapid, high-precision fabrication of parts, devices and instruments. Students, faculty and staff will have access to a five-axis mill accurate to 1 micron throughout its working volume, a five-axis waterjet cutter for all materials up to 2m x 3m x 300mm thick, novel tools for laser welding and cutting, large format milling, CNC turning, and more.

Contact Technical Sciences Administration, tsacore@uoregon.edu.

The Knight Campus’ 3D printing facility provides printers and fabrication tools that make it possible to perform additive construction and manufacturing for a variety of resins, nylon, and bio compatible materials. State-of-the-art additive manufacturing capabilities include polymer 3D printing with a voxel size of 1 micron and smaller, a composites printer for fiber-reinforced industrial-grade components, and a Two-Photon Polymerization (2PP) printer to produce filigree structures of nearly any 3D shape.

Contact Technical Sciences Administration, tsacore@uoregon.edu.

The Knight Campus features a research clean room to support the fabrication of next-generation micro-and nano-scale devices on traditional semiconductor substrates as well as soft materials. Additionally, users will be able to leverage the equipment and process capabilities to create integrated microsystems, bioengineering devices and broad work on broad areas of nanotechnology including nanoelectronics, nanophotonics, and nanobiotechnology. An environmental SEM capable of electron beam patterning is available within the facility.

The X-ray imaging facility provides versatile non-destructive X-ray based 2D and 3D imaging and quantitative analysis of biological samples and other materials at high resolution. This facility includes: a Zeiss Xradia 620 Versa (ex vivo microCT/X-ray microscopy specimen scanning of a wide range of sample dimensions and material types at voxel sizes ranging from sub-micron to hundreds of microns), a Scanco vivaCT80 (in vivo live animal longitudinal microCT imaging at voxel sizes in the tens to hundreds of microns), and a Faxitron Ultrafocus (in vivo live animal projection radiographs).

Contact Angela Lin, Senior Research Engineer, al81@uoregon.edu.

The UO’s Knight Campus collaborates closely with scientists on the UO’s main campus, including use of the additional research core facilities.